This strategic approach not only ensures optimal stock levels but also contributes significantly to preventing overstock situations. By systematically addressing obsolete inventory, you can enhance your overall inventory management practices, maximizing both space and cost efficiency. Sharing accurate sales forecasts with vendors ensures streamlined production cycles. You can also opt for domestic suppliers and place more frequent, smaller purchase orders for quicker fulfillment, reducing lead times.

Multichannel Inventory Control for Ecommerce

- Established companies can rely on historical sales data to calculate the above.

- This ties up cash you could be using for other things, like marketing or new product development.

- In the end, it helps the logistics manager to calculate optimal stock levels and the optimal order volume for each supplier.

- That means having the right product in stock, shipped on time, and delivered with no issues.

By embracing new technologies and staying informed about emerging trends, businesses can optimize their minimum stock levels for a more efficient and responsive supply chain. Remember, proactive and data-driven management of minimum stock levels is no longer a luxury, it’s a necessity. As you can see, calculating your minimum inventory levels is a critical part of running a successful business. By using the formula above, you can ensure that you always have enough products in stock to meet customer demand.

Want to take your inventory management to the next level?

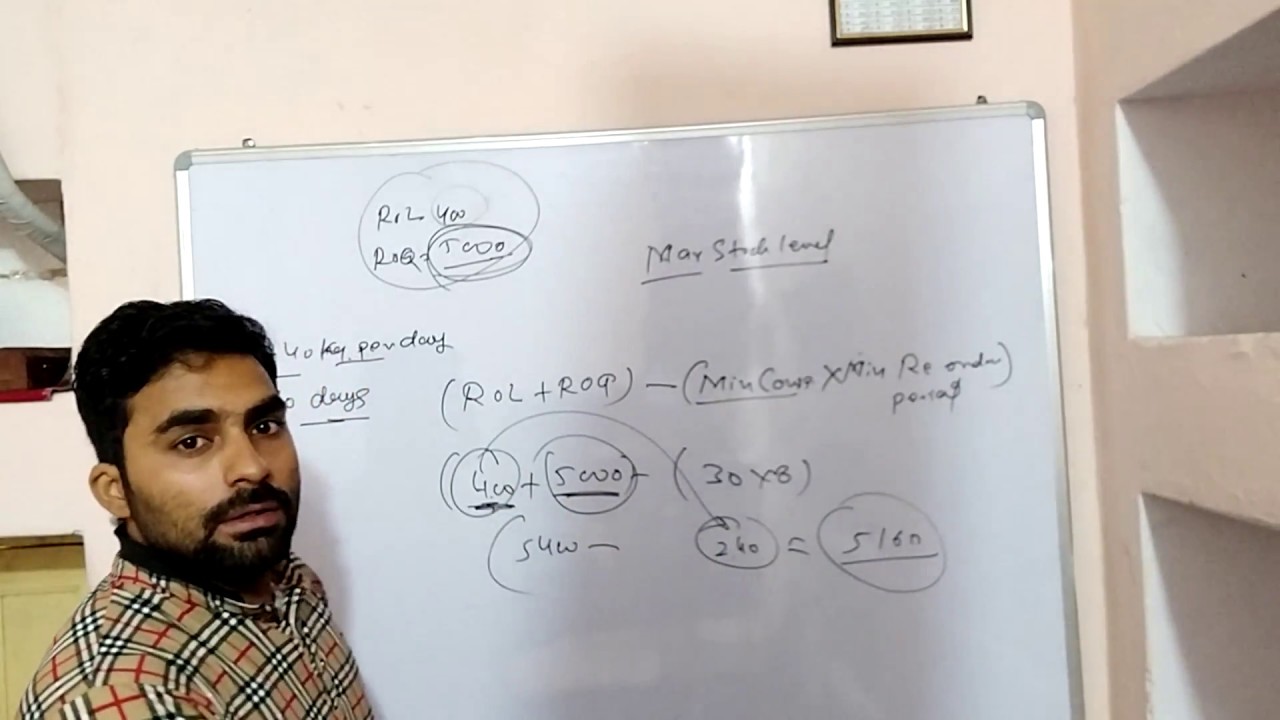

For instance, if storage space is too expensive in your area, you could rent auxiliary space farther away to keep surplus stock. This lets you keep inventory at its maximum level without breaking the bank. An item’s reorder point, or the point at which you order additional stock, may vary based on seasonal or economic factors. For instance, you might bump up your average stock level after rolling out new sales channels. A sporting goods company might keep 100 to 130 tennis rackets in its warehouse and automatically reorder from its supplier when the stock dips below 110. If a store has a maximum stock level of 200 items and a minimum of 50, the average stock level is 125 items.

Classify and prioritise your inventory in the warehouse

There, you achieve optimal inventory levels and only carry units guaranteed to sell. The reliability of suppliers in delivering orders on time and in full can also influence min and max stock levels. Unreliable suppliers may necessitate higher safety stock levels to compensate for potential delays or shortages.

A healthy stock level lets you reliably fulfill customer orders without losing money on excess warehouse space or expiring items. You may need several quarters of sales data to ascertain a specific product’s optimal stock level. Let’s say that you set your minimum stock level too high, you might end up with a warehouse overflowing with, well, everything.

Why do you need to know your minimum inventory level?

A future-oriented digital operations platform such as Actindo Core1 enables you to automatically calculate minimum stock levels based on data histories from all sales channels. Before calculating inventory levels, conduct an inventory audit to ensure all warehouse operations are in order. All the products in a warehouse should be accounted for and aligned with financial accounts. During an inventory audit, it can be beneficial to group products into separate classifications to help organize optimal inventory levels later. You reach a danger level when your inventory falls below your minimum stock level, posing a risk to business operations.

The articles and research support materials available on this site are educational and are not intended to be investment or tax advice. All such information is provided solely for convenience purposes only and all users thereof should be guided accordingly. Learn how to effectively manage orders for ecommerce with an order management system. 📌 Planning your inventory during peak demand periods like BFCM can be especially challenging. If you need a guide to help you prepare before, during, and after BFCM, check out the Inventory Planning Playbook for BFCM.

The goal is to strike a balance between maintaining adequate stock levels and minimizing carrying costs. By accurately calculating and adjusting min and max stock levels, businesses can optimize their inventory management practices and achieve better financial performance. Also, timely communication with suppliers and warehouse management fosters collaboration, contributing to optimal minimum inventory levels without excess storage costs.

That’s why successful brands, retailers and manufacturers rely on scalable, composable IT systems and distributed order management to cover all processes efficiently and precisely. Rough estimates are not enough for successful e-commerce, once you have multiple sales channels, high order volumes and a broad range of product SKUs. While seasonal fluctuations are common, recent years have shown that supply and demand in e-commerce remain highly volatile, and acute supply bottlenecks are commonplace. For a more detailed breakdown of how SkuVault Core can level up the logistics in your organizations, check out this page to go deeper.

Most retail brands rely on spreadsheets to forecast sales and determine optimal inventory. Knowing your WOS prevents lost revenue by ensuring you always replenish at the right time to avoid a stockout. Similarly, it keeps excess inventory from accumulating by ensuring you don’t place POs how to find a good accountant for your small business sooner than needed. Having the right amount of inventory on hand means none of your generated demand goes unfilled. Instead, you always have exactly what your customers what at the moment they want it. AKA the goldilocks zone where your ecommerce brand can reach peak profitability.